Klinger

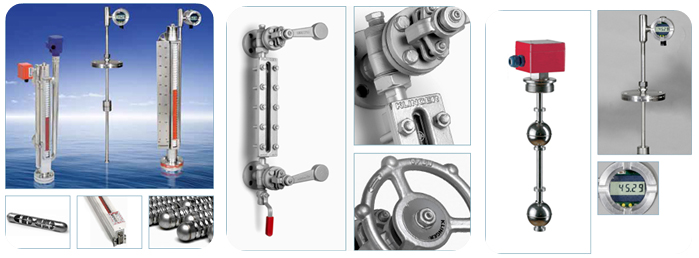

The Klinger range of Steam Level Gauges comprises of four main types:

- Glass Tube ( up to 17 bar )

- Reflex ( up to 32 bar )

- Transparent ( up to 120 bar )

- Bi Color ( up to 180 bar )

1. Reflex (up to 250 bar)

2.Transparent (up up 250 bar)

Plus a range of shut off fittings and accessories

Klinger also manufactures the well proven Magnetic Level Gauge which is particularly suitable for duties where dangerous and toxic liquids or gases are involved and where some of the following features, benefits and options are required:

Immediate and accurate response to level changes, giving clear and sharp legibility.

Continuous control of liquid level

Local and remote display

Alarm switching facilities

Robust, shockproof and completely sealed for safety

No leakage to atmosphere

Particularly suitable for dangerous or toxic fluids

Powerful omni-direction magnet system – guide – free float

Display can be rotated through 360° irrespective of float position

Automatic float warning

High pressure capability – up to 200 bar unvented

Unlimited length

Top mounted options

PTFE/PFA lined, PP, PVDF and uPVC versions

Simple to engineer and easy to install

Eliminates preventative maintenance

An economical alternative to conventional level gauges and other level measuring systems

- Liquid Level Gauges

- Magnetic Level Gauges

- Sight Glasses

- Process Level Gauges

- Steam Level Gauges